SMT assembly

We are your strategic valuable partner: Rely on our technical skills, our optimised manufacturing processes and our many years of expertise.

Printing and labelling station

Stencil printer - DEK Horizon 03i

- Full automatic stencil printer for solder paste application with input and output station

- Optical justification of the PCB

- 2D-inspection for checking the solder paste printing

- Integrated stencil cleaning system

- Vario-Grid PCB support

Automatic placement machine - Fuji NXT II

- 6 high speed component modules

- Capacity up to 40000 components/hour

- Placing accuracy up to a tolerance of 0,05mm

- Placement of components of size 0201 and smaller

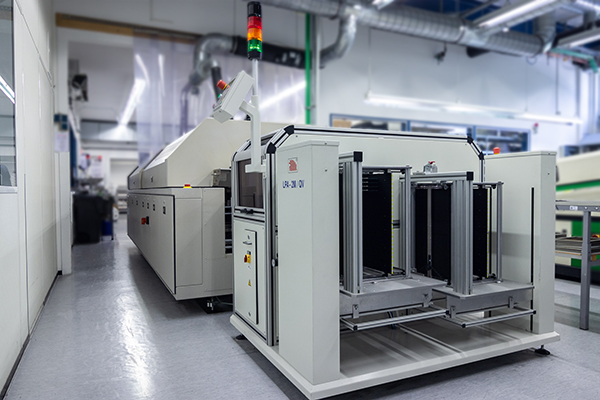

Reflow soldering installation - VXS Nitro Type 523

- Full convection reflow soldering machine for SMD-assembled PCBs

- 5 pre-heating, 2 peak and 3 cooling zones

- Soldering in nitrogen atmosphere

- PCB transport with automatic setting of the PCB-width

Automatic Optical Inspection

- Full automatic optical inspection system (AOI) for control of assembled/soldered PCBs

- Orthogonal module with 4 cameras, angular perspective with 8 cameras

- Offline programming

- Check of polarity, soldering and placement of components

Stencil cleaning system

- Compact cleaning system for products sized 780 x 950 mm

- Cleaning screen stencils, misprints, solder carriers and screen squeegees of SMD paste, SMD glue, fluxes or dust